Objective:

- Construct a system capable of controlling a CNC machine using closed feedback control loops.

- Build the controller to run on a bare metal environment on the RaspberryPi module.

- Design the code to abstract away hardware so that it is possible to run on an arbitrary CNC.

Demonstration Video

Introduction to the CNC Controller

We built a CNC controller in bare metal capable of reading in a GCode file, interpolating motor positions, and setting the motors to move a spindle to those positions in a closed feedback loop. In order to accomplish this in a bare metal environment, the RaspberryPi needed to be configured to setup the parts of the processor's peripherals that would be needed - timers, interrupts, UART controller, GPIOs, etc. Once configured, we were able to start building out modules to handle path planning and stepper motor control.

Code Appendix

The entire code for the project is held on a public GitHub repository linked here.

Bill of Materials

| Part | Quantity | Price | Link |

|---|---|---|---|

| RaspberryPi 2 | 1 | $0 | Provided |

| Jumers, Wires, Breadboard | - | $0 | Provided |

| ams AS5161 Absolute Encoder | 3 | $28.02 | Link |

| D82DIA Diametric Magnet (for encoders) | 3 | $3.39 | Link |

| TOTAL: | - | $31.41 | - |

References and Acknowledgements

Professor Joe Skovira

grbl

nraynaud's GCode Simulator

Valvers tutorials on bare metal programming

David Welch

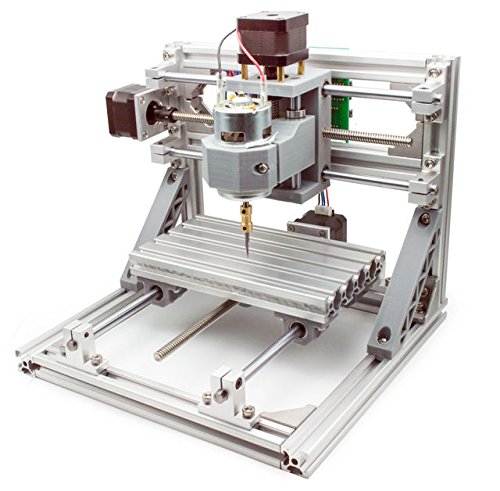

Image of CNC Machine

Image of Wood

Bootstrap

Contact

Nikita Ermoshkin

ne75@cornell.edu

Worked on developing the bare metal environment, including the ARM startup code, as well as the stepper driver for the motion control system.

Brendan Quinn

bjq6@cornell.edu

Designed and implemented the positioning software, including GCode parsing for path interpretation and step interpolation.