Code and Parts

FinalDemo.py

#!/usr/bin/python

# Final Script to Control All functions of the Autonomous Robot

from picamera import PiCamera

from picamera.array import PiRGBArray

import RPi.GPIO as GPIO

import smtplib

import time

import math

import os

# Importing OpenCV

import cv2

import cv2.cv as cv

import numpy as np

import sys

# GPIO setup

GPIO.setmode(GPIO.BCM) # set as broadcom

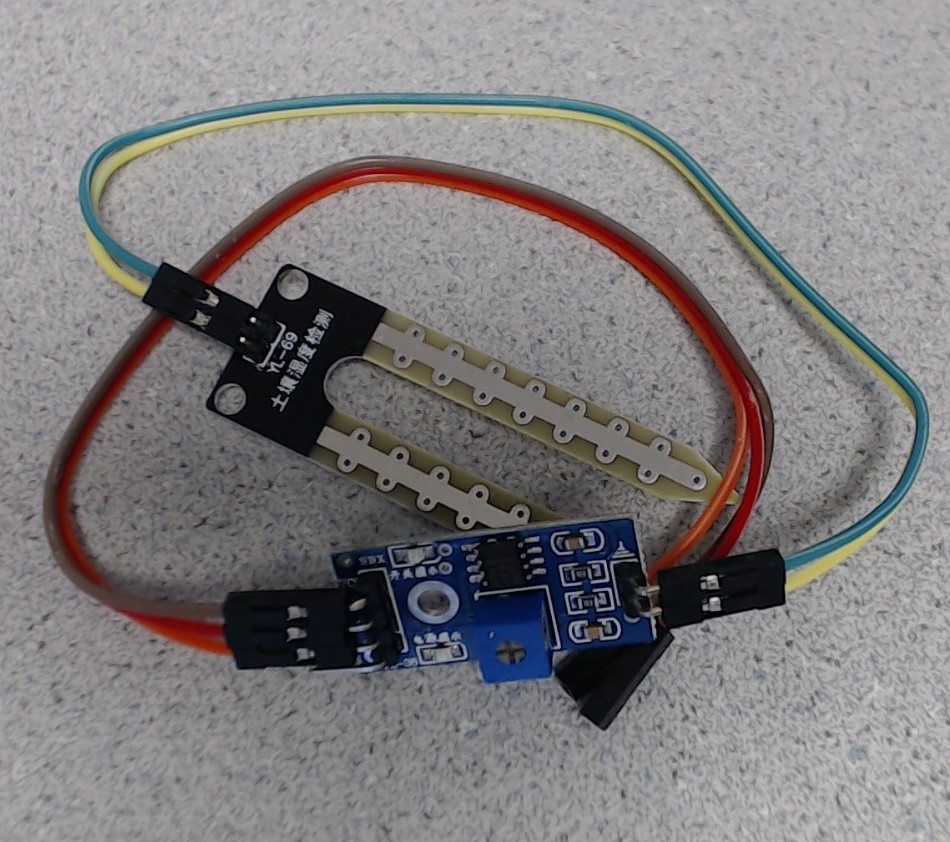

# Define the BCM channels for sensors

sensor1 = 17 #green

sensor2 = 27 #red

sensor3 = 22 #yellow

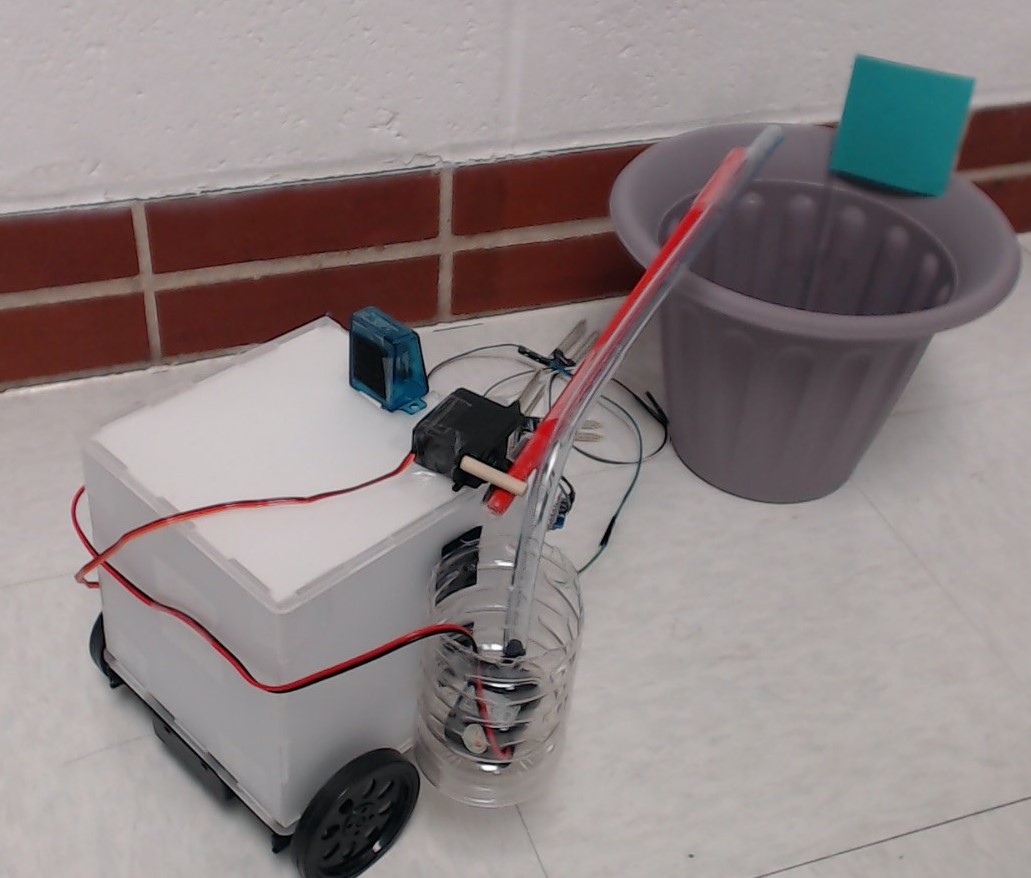

# Define the BCM channel for the water pump

pump = 26

# Initialize the GPIOs

GPIO.setup(sensor1, GPIO.IN, pull_up_down=GPIO.PUD_UP)

GPIO.setup(sensor2, GPIO.IN, pull_up_down=GPIO.PUD_UP)

GPIO.setup(sensor3, GPIO.IN, pull_up_down=GPIO.PUD_UP)

GPIO.setup(6, GPIO.OUT)

GPIO.setup(13,GPIO.OUT)

GPIO.setup(5, GPIO.OUT)

GPIO.setup(pump, GPIO.OUT)

# Define the pulse, duty cycle, and frequency calculations

hc = 0.00130

hdcC = hc/(hc + 0.02)*100

hfrC = 1/(0.02 + hc)

ha = 0.00165

hdcA = ha/(ha + 0.02)*100

hfrA = 1/(0.02 + ha)

qc = 0.001472

qdcC = qc/(qc + 0.02)*100

qfrC = 1/(0.02 + qc)

qa = 0.00155

qdcA = qa/(qa + 0.02)*100

qfrA = 1/(0.02 + qa)

pulse = 0.0015

dc = pulse/(pulse+ 0.02)*100

fr = 1/(0.02 + pulse)

pL = GPIO.PWM(6,fr)

pR = GPIO.PWM(13,fr)

arm = GPIO.PWM(5,fr)

# Start servos as close to stop

pL.start(0)

pR.start(0)

arm.start(0)

# FUNCTIONS

def moveArm(t):

arm.ChangeDutyCycle(qdcC)

arm.ChangeFrequency(qfrC)

curTime = time.time() + t

while time.time() < curTime:

pass

arm.ChangeDutyCycle(0)

def backArm(t):

arm.ChangeDutyCycle(qdcA)

arm.ChangeFrequency(qfrA)

curTime = time.time() + t

while time.time() < curTime:

pass

arm.ChangeDutyCycle(0)

def turnLeftSlow(t):

pL.ChangeDutyCycle(hdcC)

pL.ChangeFrequency(hfrC)

pR.ChangeDutyCycle(hdcC)

pR.ChangeFrequency(hfrC)

curTime = time.time() + t

while time.time() < curTime:

pass

pL.ChangeDutyCycle(0)

pR.ChangeDutyCycle(0)

return

def turnRightSlow(t):

pL.ChangeDutyCycle(hdcA)

pL.ChangeFrequency(hfrA)

pR.ChangeDutyCycle(hdcA)

pR.ChangeFrequency(hfrA)

curTime = time.time() + t

while time.time() < curTime:

pass

pL.ChangeDutyCycle(0)

pR.ChangeDutyCycle(0)

return

# Green Sensor callback

def sensor1_callback(channel):

if GPIO.input(channel):

print "sensor1 on"

else:

print "sensor1 off"

if("sensor1" not in needsWater):

needsWater.append("sensor1")

# Red Sensor callback

def sensor2_callback(channel):

if GPIO.input(channel):

print "sensor2 on"

else:

print "sensor2 off"

if("sensor2" not in needsWater):

needsWater.append("sensor2")

# Yellow Sensor callback

def sensor3_callback(channel):

if GPIO.input(channel):

print "sensor3 on"

else:

print "sensor3 off"

if("sensor3" not in needsWater):

needsWater.append("sensor3")

GPIO.add_event_detect(sensor1, GPIO.FALLING, callback=sensor1_callback, bouncetime=300)

GPIO.add_event_detect(sensor2, GPIO.FALLING, callback=sensor2_callback, bouncetime=300)

GPIO.add_event_detect(sensor3, GPIO.FALLING, callback=sensor3_callback, bouncetime=300)

# Define OpenCV capture video

cap = cv2.VideoCapture(0)

# Define the queue

needsWater = []

i = 0

now = time.time()

adjust = 1

# Define cx and cy

cx = -1

cy = -1

# Start with state 0, initializing, and try to find (non-existant black tag)

state = 0

findColor = 'black'

blackLB = (0,0,0)

blackUB = (0,0,0)

colorLB = blackLB

colorUB = blackUB

# Define the half size of the screen

halfScreen = 350

##### INITIALIZE VIDEO AND CAPTURE TO RGB MATRIX #####

global camera, rawCapture

camera = PiCamera()

camera.framerate = 15

rawCapture = PiRGBArray(camera)

time.sleep(0.5)

########### COLOR MAIN LOOP RECOGNITION ##############

pixel_size = 200

for frame in camera.capture_continuous(rawCapture, format="bgr", use_video_port = True):

image = frame.array

imageRaw = image.copy()

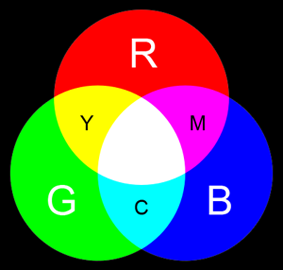

greenLB= (50,100,0)

greenUB = (100, 255, 140)

redLB = (169,136,103)

redUB = (179,225, 206)

yellowLB = (10,50,100)

yellowUB = (80,230,230)

if(findColor == "red"):

colorLB = redLB

colorUB = redUB

elif(findColor == "yellow"):

colorLB = yellowLB

colorUB = yellowUB

elif(findColor == "green"):

colorLB = greenLB

colorUB = greenUB

else:

colorLB = blackLB

colorUB = blackUB

hsv = cv2.cvtColor(image, cv2.COLOR_BGR2HSV)

mask = cv2.inRange(hsv, colorLB, colorUB)

mask = cv2.erode(mask, None, iterations =2 )

mask = cv2.dilate(mask, None , iterations =2 )

# Ensure no stray element is detected as tag

contours = cv2.findContours(mask.copy(), cv2.RETR_EXTERNAL, cv2.CHAIN_APPROX_SIMPLE)[-2]

for c in contours:

if cv2.contourArea(c) > pixel_size:

################# CENTROID OF THE TAG ##################

M = cv2.moments(c)

cx = int(M["m10"]/ M["m00"])

cy = int(M["m01"] / M["m00"])

# Define contour and center

cv2.drawContours(image, [c] , -1, (0,255,255), 2 )

cv2.circle(image, (cx,cy), 7, (255,255,255), -1 )

# Display on console for debugging

#cv2.imshow("RAW", imageRaw)

#cv2.imshow("Threshold", mask)

#cv2.imshow("overlay", image)

print cx, cy

key = cv2.waitKey(1) & 0xFF

rawCapture.truncate(0)

if( key == ord("q") ):

break

print needsWater

print state

print findColor

###################### STATE MACHINE #########################

# STATE 0: Initializing

if state == 0:

if needsWater == []:

findColor = 'black'

cx = -1

cy = -1

elif needsWater[0]=='sensor2':

cx = -1

cy = -1

state = 4

findColor = 'red'

elif needsWater[0] == 'sensor1':

cx = -1

cy = -1

state = 2

move = 1

findColor = 'green'

elif needsWater[0] == 'sensor3':

cx = -1

cy = -1

state = 1

move = 1

findColor = 'yellow'

else:

findColor = 'black'

cx = -1

cy = -1

# STATE 1: Turn Left towards Yellow/Sensor3

elif state == 1:

if cx > 0 and cy > 0:

state = 3

elif move == 1:

turnLeftSlow(0.3)

now = time.time() + 1

move = 0

elif time.time() >= now:

move = 1

else:

pass

# STATE 2: Turn Right towards Green/Sensor1

elif state == 2:

if cx > 0 and cy > 0:

state = 3

elif move == 1:

turnRightSlow(0.2)

now = time.time() + 1

move = 0

elif time.time() >= now:

move = 1

else:

pass

# STATE 3: Adjusting

elif state == 3:

if cx < (halfScreen*1.1) and cx > (halfScreen*0.9):

if findColor == 'yellow' or findColor == 'green':

state = 4

elif findColor == 'red':

state = 0

else:

pass

elif cx > (halfScreen*1.1) and adjust == 1:

turnRightSlow(0.1)

adjust = 0

adjustTime = time.time() + 1

elif cx < (halfScreen*0.9) and adjust == 1:

turnLeftSlow(0.1)

adjust = 0

adjustTime = time.time() + 1

else:

if time.time() >= adjustTime:

adjust = 1

# STATE 4: WATERING PLANT

elif state == 4:

# Lowers arm and turns on pump

moveArm(0.7)

GPIO.output(pump, True)

time.sleep(1)

# Turns off pump and raises arm

GPIO.output(pump, False)

backArm(0.6)

# Remove from queue

if(findColor == 'red'):

needsWater.remove('sensor2')

print 'Was here'

elif(findColor == 'green'):

needsWater.remove('sensor1')

print 'remove sensor1'

elif(findColor == 'yellow'):

needsWater.remove('sensor3')

print 'remove sensor3'

else:

pass

state = 5

# STATE 5: Return to center

elif state == 5:

if findColor == 'yellow':

findColor = 'red'

cx = -1

cy = -1

state = 2

elif findColor == 'green':

findColor = 'red'

cx = -1

cy = -1

state = 1

# If red

else:

state = 0

cx = -1

cy = -1

findColor = 'black'