|

|

Copyright 2006 Cornell University. All rights reserved.

|

Purchasing variables should be considered in addition to the material specifications. These include: volume requirements; cost, payment terms, shipping options and costs, and lead time considerations based on location and production capacity.

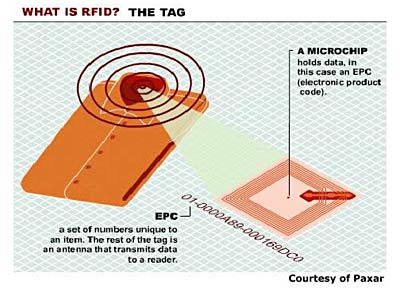

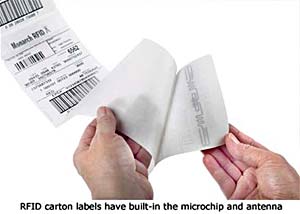

SKU's (Stock Keeping Units) SKU is a practical unit that most retailers use to organize their buying and stock. It means the smallest unit of variation in a purchase or inventory. Each SKU is an individual style, size, and color, such as one red sweater in size 10. SKU's allow businesses to keep track of orders and inventory for the purpose of purchase, stock, and reorder. Advancements in information technology are making it possible to track at the individual article level rather than at the SKU level using either bar codes or radio frequency identification (RFID) tags. Tracking is especially important for mass customization, because a business can follow a single garment order from design through production and delivery.

Volume Requirements A second consideration is how much material inventory you need to keep on hand. Think of inventory as an investment. It costs money to keep material on hand. If you are making products based on orders, it is easier to keep a smaller amount of fabric inventory and order the fabric as the orders come in, depending upon lead time requirements. If you make products for stock, you will need to purchase fabric before you know your sales volume so you will need to forecast how much fabric you will need. Most companies use the past year's orders for similar products to forecast future sales. More accurate and progressive forecasting models use

Generally, it is a good financial decision to keep only a small inventory of fabric. Basic fabric that will be used year after year could be bought ahead if the quantity discounts offset the carrying costs.

If you are interested in considering off-shore production, the materials and labor are often purchased together as a full-package. Therefore, the decision to purchase off-shore production in a particular country might be influenced by the quality and type of materials available in that particular country. Cost It is easy to get caught up in all of the beautiful fabrics--Carol Young calls trade shows playgrounds for designers. But remember, it doesn't matter how much you love the fabric if you don't sell any of your products because they are too expensive. Payment Terms |

For small businesses, it is important to start with a small number of SKU's. For example, minimums are usually required by color, so the more colors you order, the higher your minimums. Production logistics and costs will also increase as you increase style and size SKU's.

For small businesses, it is important to start with a small number of SKU's. For example, minimums are usually required by color, so the more colors you order, the higher your minimums. Production logistics and costs will also increase as you increase style and size SKU's.