|

Copyright 2006

Cornell University.

All rights reserved.

|

Mass customization is a new approach to manufacturing and providing services that is revolutionizing business. As consumers and retailers demand more individualized products and services, apparel producers are rethinking their approaches to products and manufacturing processes.

A key component in mass customization is the reduction of time from order to delivery. Davis (1987) describes the time rules of mass customization as:

Let’s explore mass customization options in apparel production by the points at which customers become involved in the production process as is illustrated in the apparel mass customization model below.

Mass customization involves customers more than mass production. For example, consumers and retailers help in the design process by selecting garment details, fabrics or size measurements for clothing items. Mass customization requires

enabling technologies for production,

information, and communication. Here is an

expanded list of these technologies that

support product development, production,

orders, distribution.

Mass customization shortens production time and increases production efficiency while creating an individualized product or service. Its technologies reduce order to delivery time while increasing individuality. Mass customization can be the basis for an entire business (e.g. IC3D.com, Timbuktu.com) or one piece of the business (e.g., Lands’ End). Producers can adapt their design and production processes to incorporate some mass customized products or services. For example, retailers might request a current style to be ordered with a different fabric or sleeve. Or they continuously replenish their inventory with orders based on past consumer purchases. Patterns Stage Mass customization at the pattern stage is made possible with enabling technologies such as computer-aided design (CAD), digital printing, single ply,

Digital textile printing allows for unique designs to be printed onto pre-cut fabric that is then cut and sewn into unique apparel items. Apparel producers would have pattern pieces ready for printing when a customer order for a particular print is received. This would save time in the production process where apparel producers currently purchase textile goods months in advance, without being sure any customer will order a particular print.

Single ply, automated cutting equipment and flexible manufacturing strategies are also essential to mass customization. While the advantage of mass production is high volume in one style, the advantage of mass customization is flexible, time-sensitive production without wasteful inventory. Apparel articles are produced only for order and the orders may be for as few as one or two pieces. Current Industry Examples of Patterns Design Stage

Component choice mass customization gives the power of choice to the consumer, retailer, or business customer within limits. The manufacturer may limit customer options by offering only fabric choices or sleeve style choices or size choices. Or the apparel producer can offer customers all three options. The important point is that the customer is involved at the design stage and chooses from a number of alternatives. Your-T is an example of a component choice e-commerce website. Note this interactive site on the Designers as Entrepreneurs site under your-T button. I would like this to be more obvious so that people can get to it in different ways. Current Industry Examples of Design Production Planning

Mass Customization strategies at the Production Planning stage and later at the Point-of-Sale (POS) stage are enabled by electronic links among the departments of an apparel producer and between the producer and its customers. Major retailers currently use EDI or electronic data interchange for ordering, invoicing, and shipping. These EDI links, and now Internet links, can be used to collect consumer purchase data and to base production plans on this information. Apparel producers traditionally operated on a 66-week production cycle, from design and ordering fabric to customer delivery. Mass customization can increase competitiveness by shortening this production time through production planning strategies. Forecasting future orders based on consumer purchases is one mass customization strategy. Testing styles and fabrics with retail customers during the pre-season provides valuable information used to plan (or mass customize) production. Basic styles and styles identified by retailers for which an apparel producer is certain to get orders can be produced early in the season. Then, production time is free later in the season for the styles that sell very well and are reordered. The goal is to make enough pieces of the styles that sell and will be reordered and not make too many pieces of the styles that will not sell. Current Industry Examples of Production Assembly Stage

Apparel customers can become involved in mass customization at the manufacturing stage if they want to repeat an order in a small quantity or with new fabrics. These small lot orders could take the form of basic styles that are reordered each year or during the season with new and well-received colors and fabrics or slight style modifications. The design and patterns already exist so the order is easily repeated using CAD equipment and sent directly to assembly? Flexible manufacturing strategies such as modular manufacturing increase the efficiency of small order production. Current Industry Examples of Assembly Distribution

With the advent of bar codes and electronic data interchange (EDI), consumer point-of-sale (POS) information is available to both retailer and apparel producer. This information opens up the possibility of delivering apparel goods to retail customers based on their sales and inventory needs. Current Industry Examples of Distibution Mass customizing the delivery of apparel goods could revolutionize retailing by changing its basic assumptions. Rather than assuming and planning for markdowns halfway through a selling season, retailers order a small portion of each season’s order and use consumer sales to decide which styles need to be reordered and in what sizes and colors. Some retailers study the POS data and manage their own reorders. Some retailers put apparel producers in charge of this process, called vendor- managed replenishment. Apparel producers can also use point-of-sale information to manage their own production planning based on the styles and delivery dates they predict retailers will request. Post Purchase Current Industry Examples of Post Purchase

|

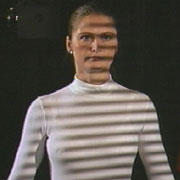

Body scanning technology collects over 200,000 3D data points to describe the body’s outer surface. These data points develop a more accurate representation of the body than the limited number of linear measurements taken with a tape measure (e.g., waist, hips, chest, back neck, etc.). And the scanning process only takes 12 seconds. Measurements compatible with computer aided design (CAD) pattern making systems are extracted

from the data cloud, permitting development of individually sized patterns.

Body scanning technology collects over 200,000 3D data points to describe the body’s outer surface. These data points develop a more accurate representation of the body than the limited number of linear measurements taken with a tape measure (e.g., waist, hips, chest, back neck, etc.). And the scanning process only takes 12 seconds. Measurements compatible with computer aided design (CAD) pattern making systems are extracted

from the data cloud, permitting development of individually sized patterns.